AWRI

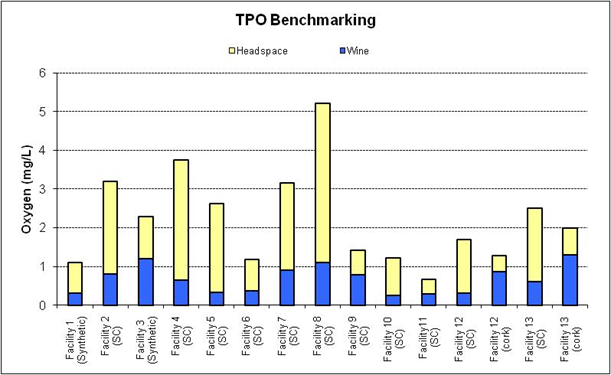

Measuring dissolved oxygen for quality assurance doesn’t give you the full story. Typical TPOs, measured by AWRI Commercial Services bottling line benchmarking service across Australian and New Zealand facilities, (link to Oxygen management, TPO benchmarking) have shown that typically over 60% of the oxygen in the bottle is in the headspace. If you are only monitoring the DO, then you are overlooking the majority of the oxygen that is getting into your wines at bottling.

All of the TPO ends up reacting with your wine, initially the oxygen dissolved in the wine matrix, then the oxygen from the headspace which must first dissolve into the wine matrix and then react with the wine constituents. The TPO value at bottling has been shown to have a significant impact on the shelf life of the wine post bottling and it can also have an impact on the wine sensory properties. An example of the impact of best practice and worst practice TPO management at bottling on wine shelf life is shown in Figure 1.

The wine bottled with an initial free SO2 level of 27 mg/L and industry worst practice oxygen management at bottling, a TPO of 5 mg/L, appears to approacing its shelf life after only 4 months in the bottle!

How to measure TPO

Total package oxygen at bottling can be measured in a number of ways including the following:

- Oxyluminesence technologies such as the NomaSense. The AWRI Commercial Services use the Nomasense as our reference method for conducting our TPO benchmarking studies;

- Using technologies to measure dissolved oxygen such as the Orbisphere along with appropriate bottle shaking protocols and calculations to account for the residual oxygen in the headspace. This is explained further below.

Oxygen does not completely dissolve in wine even after vigourous shaking – a significant residual amount remains in the headspace. Measuring TPO at bottling is critical, however many wineries only have equipment that enables them to measure the dissolved oxygen phase. To assist these wineries effectively manage their bottling operations using their existing equipment the AWRI Commercial Services have developed a method to approximate the TPO using our TPO calculator (Access the TPO calculator fact sheet).

This new method involves thoroughly shaking the bottle to establish an oxygen equilibrium between the wine and the headspace. Once equilibrated, the headspace retains some oxygen, as not all of the oxygen can dissolve in the liquid. The DO is measured using a standard Orbisphere or similar technology and entered into the online calculator (access the Total Package Oxygen calculator), along with the following:

- fill height

- temperature

- bottle volume

- wine colour

With these inputs, an approximate TPO value is provided through our correlation developed using the NomaSense reference method.